Warp Knitting

Warp knitting is the sequential formation and interlinking of loops in an axial direction on a lateral array of needles with at least one separate thread being supplied to each needle. The loops are joined together in a width-wise direction by moving the threads back and forth between adjacent needles.

Warp knitting is a specialized textile production technique that has been in use for centuries. It differs from traditional weft knitting in that it involves multiple yarns running vertically (warp) to create a fabric with interconnected loops. This article provides an introduction to warp knitting, tracing its historical roots and explaining its significance in modern textile manufacturing.

Warp knitting is a specialized textile production technique that has been in use for centuries. It differs from traditional weft knitting in that it involves multiple yarns running vertically (warp) to create a fabric with interconnected loops. This article provides an introduction to warp knitting, tracing its historical roots and explaining its significance in modern textile manufacturing.

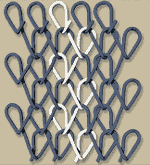

Warp knitting represents the fastest method of producing fabric from yarns. Warp knitting differs from weft knitting in that each needle loops its own thread. The needles produce parallel rows of loops simultaneously that are interlocked in a zigzag pattern. The fabric is produced in sheet or flat form using one or more sets of warp yarns. The yarns are fed from warp beams to a row of needles extending across the width of the machine. Two common types of warp knitting machines are the Tricot and Raschel machines. Raschel machines are useful because they can process all yarn types in all forms (filament, staple, combed, carded, etc.). Warp knitting can also be used to make pile fabrics often used for upholstery.

Warp Knit Structure

Warp knitting is defined as a stitch forming process in which the yarns are supplied to the knitting zone parallel to the selvedge of the fabric, i.e. in the direction of the wales. In warp knitting, every knitting needle is supplied with at least one separate yarn. In order to connect the stitches to form a fabric, the yarns are deflected laterally between the needles. In this manner, a knitting needle often draws the new yarn loop through the knitted loop formed by another end of the yarn in the previous knitting cycle.

Warp knitting is defined as a stitch forming process in which the yarns are supplied to the knitting zone parallel to the selvedge of the fabric, i.e. in the direction of the wales. In warp knitting, every knitting needle is supplied with at least one separate yarn. In order to connect the stitches to form a fabric, the yarns are deflected laterally between the needles. In this manner, a knitting needle often draws the new yarn loop through the knitted loop formed by another end of the yarn in the previous knitting cycle.

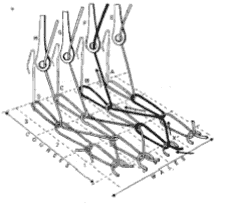

A warp knitted structure is made up of two parts. The first is the stitch itself, which is formed by wrapping the yarn around the needle and drawing it through the previously knitted loop. This wrapping of the yarn is called an overlap. The diagram shows the path taken by the eyelet of one yarn guide traveling through the needle line, making a lateral overlap (shog) and making a return swing. This movement wraps the yarn around the needle ready for the knock-over displacement.

The second part of stitch formation is the length of yarn linking together the stitches and this is termed the underlap, which is formed by the lateral movement of the yarns across the needles.

The length of the under lap is defined in terms of needle spaces. The longer the underlap, the more it lies at right angles to the fabric length axis. The longer the underlap for a given warp the greater the increase in lateral fabric stability, conversely a shorter under lap reduces the width-wise stability and strength and increases the lengthways stability of the fabric.

The length of the underlap also influences the fabric weight. When knitting with a longer underlap, more yarn has to be supplied to the knitting needles. The underlap crosses and covers more wales on its way, with the result that the fabric becomes heavier, thicker and denser. Since the underlap is connected to the root of the stitch, it causes a lateral displacement in the root of the stitch due to the warp tension. The reciprocating movements of the yarn, therefore, cause the stitch of each knitted course to incline in the same direction, alternately to the left and to the right.

In order to control both the lateral and longitudinal properties, as well as to produce an improved fabric appearance with erect loops, the second set of yarns is usually employed. The second set is usually moved in the opposite direction to the first in order to help balance the lateral forces on the needles. The length of the underlap need not necessarily be the same for both sets of yarns.

Warp Knitting Machines

Warp knitting machines are at the heart of the warp knitting process. This section explores different machine configurations, the role of guide bars in controlling yarn movement, and the modernization and automation of warp knitting technology.

Types of Warp Knitting

Warp knitting encompasses various techniques, each with its own characteristics and applications. We’ll delve into the most common types of warp knitting, including tricot, raschel, Milanese, crochet, Rachel, and others, highlighting their distinct features.

Warp Knitting Processes

Understanding the warp knitting process is essential for appreciating the complexity and precision involved. We’ll discuss warp setting and warping, stitch formation, the crucial role of guide bars in pattern creation, and finishing processes that enhance the final fabric’s quality.

Characteristics of Warp-Knitted Fabrics

Warp-knitted fabrics possess unique characteristics that make them desirable for specific applications. We’ll explore their stability and strength, versatility, textural variety, and elasticity, showcasing the advantages that warp knitting offers.

Applications of Warp Knitted Fabrics

The versatility of warp-knitted textiles makes them suitable for a wide range of applications. We’ll examine their use in apparel and lingerie, technical textiles for industrial purposes, home furnishings, automotive interiors, sports and outdoor gear, and medical textiles.

Advantages and Disadvantages

Warp knitting offers several advantages, such as high productivity and fabric stability. However, it also has limitations and challenges. We’ll provide a balanced overview of both the advantages and disadvantages of warp knitting.

Innovations in Warp Knitting

The textile industry is continually evolving, and warp knitting is no exception. This section discusses recent innovations in warp knitting, including sustainable practices, the development of smart and functional textiles, and the possibilities of customization and 3D knitting.

Conclusion

In conclusion, warp knitting remains a vital and evolving technique in the world of textiles. Its unique characteristics and versatility make it a valuable tool for various industries. As technology advances and sustainability becomes increasingly important, warp knitting is poised to play an even more significant role in the future of technical textiles and fabric production.

mat mil mat mil gul se mayt mil eee gulgul bismil………………………….